Electrostatic (ESL) Theory

Jump To

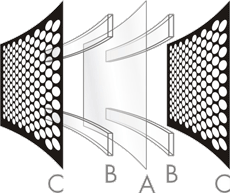

Parts of an Electrostatic Transducer

- A) Diaphragm

- B) Spars

- C) Stators

Electrostatic Forces at Work

Opposite charges attract. Like charges repel. The diaphragm holds a constant positive charge. Here are some comparisons to consider:

Quick Facts

The diaphragm material used in a MartinLogan transducer is only 12 microns thick (0.00048 inches). Here are some facts to consider for comparison:

Kitchen cling wrap is 11-15 microns thick.

Human hair is 100 microns thick (8 times thicker!!!)

We use an ultra-thin diaphragm because it is nearly free of mass (and thus, inertia). This becomes extremely important when you consider that a transducer might have to change direction 40,000+ times per second! And, every time a transducer changes direction it has to overcome inertia before it begins to travel in the proper direction!!! The resulting sluggishness causes a recording to sound, well, like a recording—instead of the original sonic event.

The extremely rapid response time of a MartinLogan electrostatic transducer is a major contributor to their magical sound, most often described as "sitting in the room with the musician".

Why bother? Some people (and most speaker manufacturers) wonder why anyone would make electrostatic loudspeakers when conventional ones are so much easier to design and build. It would be a silly question if ordinary dynamic speakers all performed poorly, but that's hardly the case. For applications current electrostatic technology can't handle well (subwoofers, to take an extreme example), even we employ other approaches. Cones and domes still have their place.

Wherever possible, however, we go electrostatic. It is a special breed of speaker, capable of extraordinary, compellingly realistic reproduction. In certain crucial respects, good electrostatic loudspeakers are just better than anything else available. Hear MartinLogan electrostats, properly set up in a good environment, and the difference will be immediately apparent - no explanation required.

But for those who'd like to understand as well as experience, here's the back-story. How do electrostatic loudspeakers work, and what are the benefits? Just as important, what are the problems and what has MartinLogan done to overcome them? Then you'll know why we have had such great success with these wonderful speakers, while almost nobody else even tries.

How Electrostatic Speakers Work

An electrostatic transducer has three basic components - stators, diaphragm, and spars (spacers) - assembled as a sandwich. The diaphragm is an ultra light plastic film, impregnated with an electrically conductive material and stretched taut between the two stators, which are perforated steel sheets coated with an insulator. When the speaker is operating, the diaphragm is charged to a fixed positive voltage by a high-voltage power supply, creating a strong electrostatic field around it. (If you've been puzzling over why electrostatic speakers have power cords, there's the reason).

The stators, meanwhile, are connected to the audio system's amplifier through a step-up transformer. It converts the amplifier's output to a pair of high-voltage signals of equal strength but opposite polarity. So as the charge on one stator grows increasingly positive, the charge on the other grows more negative by exactly the same amount. Because like charges repel and opposite charges attract, the diaphragm's positive charge will force it to move forward or backward depending on the stator charges. For example, when the front stator's charge is negative and the back stator's positive, the diaphragm will be pulled from the front and pushed from the back and therefore move forward. The stronger the charges on the stators, the greater the diaphragm displacement. This is how an electrostatic transducer translates an electrical audio signal into diaphragm motion to produce sound waves in the room.

To help stiffen the panel (it's very important that only the diaphragm move) and to prevent the diaphragm from ever coming too close to a stator, nonconductive strips called spars are placed widthwise at intervals along each stator's length.

Electrostatic Advantages...

The drivers in a conventional loudspeaker have diaphragms attached to coils of wire, called voice coils. Current from an amplifier flows through these coils, creating a fluctuating electromagnetic field that interacts with the field of a fixed permanent magnet to cause diaphragm motion, and thus sound. The voice coil attaches to the periphery of a dome or the apex of a cone, which means that only a small portion of the diaphragm is actually driven; the rest has to follow along. If the diaphragm is not perfectly rigid, it will tend to flex and resonate at some frequencies, causing distortion and uneven response. Yet tweeter diaphragms, especially, need to be light to allow adequate efficiency and high-frequency extension. Meeting both these theoretical requirements simultaneously is nearly impossible with real materials.

An electrostatic diaphragm, on the other hand, is driven uniformly over its entire surface, so it doesn't need to be rigid at all - it can be made as light as possible. (The diaphragm of a MartinLogan electrostat is actually lighter than the air it moves.) That, together with the transducer's distortion-canceling push-pull mode of operation, enables the diaphragm to trace even the most delicate sonic details with absolute precision. It also means that the transducer can operate over an exceptionally wide frequency range without having to cross over to another driver. Acoustical interference between drivers and the phase shift introduced by crossover filters cause frequency-response irregularities that are particularly disruptive in the midrange or lower treble, right where crossovers typically are located in conventional speakers.

Controlled Dispersion. Another key attribute of an electrostatic speaker is its naturally dipolar radiation pattern. A true dipole transducer radiates with equal intensity from the front and back of its diaphragm, but the outputs are in opposite phase. As a result, sound waves rippling out toward the sides meet at the speaker's edge and cancel. That and the relatively large size of a typical electrostatic panel cause output at the sides to be very low relative to that of a conventional loudspeaker, which in turn minimizes side-wall reflections that tend to muddle sonic detail and stereo imaging. While the reduction in output to the sides contributes to the astonishing clarity for which electrostats are revered, the energy reflected off the wall behind the speaker opens up and deepens the sound.

...and Challenges

So why is the world turned on its head? Why aren't all speaker companies making electrostatics? Consider this list of issues a designer of electrostatic speakers must confront:

Dynamics. Making an electrostatic transducer with the efficiency and output capability taken for granted in conventional electromagnetic drivers requires very intense electrostatic fields. That means charging the tightly spaced stators and diaphragm to thousands of volts. The closer oppositely charged elements are brought to each other and the stronger the charges on them, the greater the likelihood of a pyrotechnical electrical discharge. Such arcing between diaphragm and stator can seriously damage both the speaker and the amplifier driving it. Unfortunately, the diaphragm approaches a stator most closely at exactly the time when the charge difference between them (and between the two stators themselves) is greatest - when a loud signal reaches its peak!

Bass. At low frequencies, as wavelengths become large relative to panel width, the out-of-phase signals from opposite sides of the diaphragm tend to wrap around and cancel each other. So like all true dipole speakers (not to be confused with conventional-driver quasi-dipole surrounds), electrostatics are prone to weak bass. Increasing panel size helps with this, as well as with the output/efficiency problem discussed above, but there's a practical limit.

Treble dispersion. The other side of the panel-size coin: When a sound has a wavelength that is small relative to the size of the speaker diaphragm reproducing it, it tends to radiate over a narrow angle rather than dispersing widely into the room. Such high-frequency "beaming" yields a very small sweet spot where the listener can sit and hear proper tonal balance and often to a dry, sterile sound quality. Since every other consideration pushes electrostatics in the direction of larger panels, treble beaming is a serious concern.

Eh, maybe we should just throw some cones and domes in a box and call it a day.

Triumph of Technology

Well, no, we've never done that, and we're not going to start now, because MartinLogan electrostatic loudspeakers don't suffer from the problems described above. Not because we're wizards, but because we cared enough about the qualities that make electrostatic speakers special to work really hard at overcoming the various obstacles. We're just going to hit the high points here; more details are available in the individual product descriptions.

High-tech coatings and MicroPerf stators. Benefiting from our sophisticated diaphragm coatings and advanced aerospace stator insulation, MartinLogan panels can support exceptionally strong charges without arcing. In addition, the MicroPerf stators of our new XStat transducers significantly increase exposed diaphragm area (without compromising stator rigidity), enabling them to deliver the dynamics and low-frequency extension of traditional panels twice their size.

Hybrid design. Although our panel technologies enable them to operate to lower frequencies than anything other than an extremely large traditional electrostatic, they cannot reproduce deep bass as effectively as a conventional speaker of similar size. Our solution is to reproduce the lowest frequencies with a very high-quality dynamic woofer. This has always been a tricky proposition, given that the transducer technologies and radiation patterns for the two elements of a hybrid electrostatic speaker are so different. (A dynamic woofer radiates omni-directionally, whereas an electrostatic panel, being a dipole, radiates in an approximately figure-8 pattern.) In addition, other companies who have made such hybrids have often exhibited something of a Napoleon complex, overemphasizing the output from the woofer in an apparent effort to prove their loudspeaker manhood. The result of that misguided strategy is invariably thick, turgid bass that obscures midrange detail, thereby obliterating one of the main reasons for building an electrostatic speaker to begin with. We don't do that. Instead, our speakers incorporate extremely high-performance woofers, crossed over the electrostatic panels via carefully tailored, precisely calculated networks made with top-quality components. Low crossover frequencies, phase- and amplitude-optimized crossovers, and critically damped woofers ensure a seamless transition between the two types of drivers, yielding speakers that really do offer the best of both worlds.

Curvilinear Line Source panels. MartinLogan's CLS electrostatic panels are an elegant solution to the problem of achieving the preferred range of horizontal dispersion from a driver having a large diaphragm surface area. Our proprietary Vacuum Bonding technique, aerospace adhesives, and arduously developed construction methods enable us to build panels with optimum horizontal curvature, yet without compromising performance, sound quality, or structural integrity. At the same time, CLS panels maintain relatively limited vertical dispersion, which minimizes undesirable floor and ceiling reflections. And they do so naturally, without resorting to tricks such as multi-driver arrays or to horns, which create other problems of their own.

We don't claim that MartinLogan speakers are perfect - only that they are closer to perfection than any others that have ever been made. And we're working constantly to make them better. The proof of the engineering is in the listening. We encourage you to audition our work; we believe you will find it a special and rewarding experience.